Your Mission-Critical Forging Parts Manufacturers

Providing end-to-end solutions for the Automotive, Aerospace, and Energy industries—from in-house tooling design to finished, ready-to-assemble components.

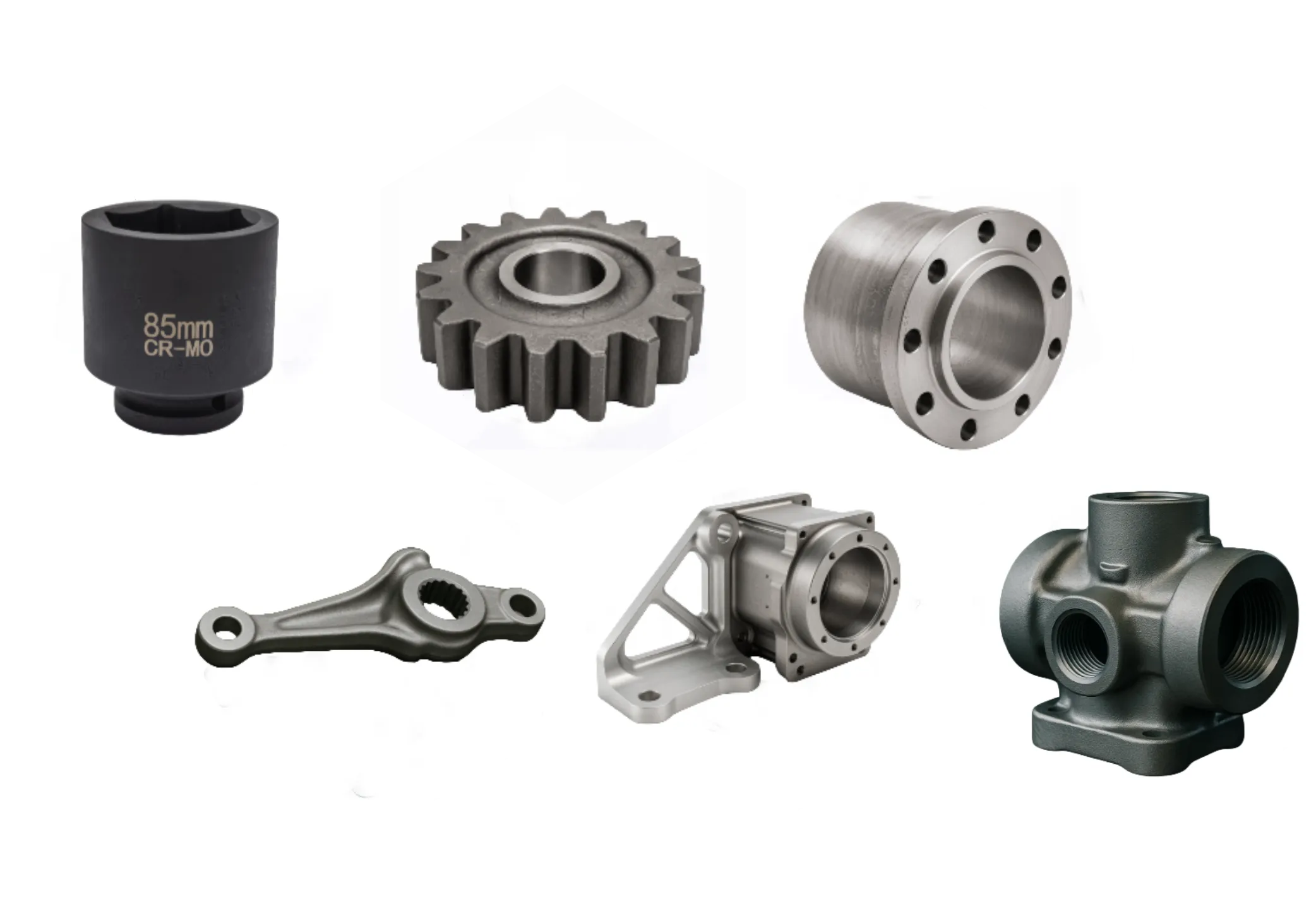

Explore Our Forged Product Lines

High-performance forged components for global OEM and industrial applications — covering flanges, crankshafts, connecting rods, shafts, rings, valve bodies, gears, fasteners, and custom forgings.

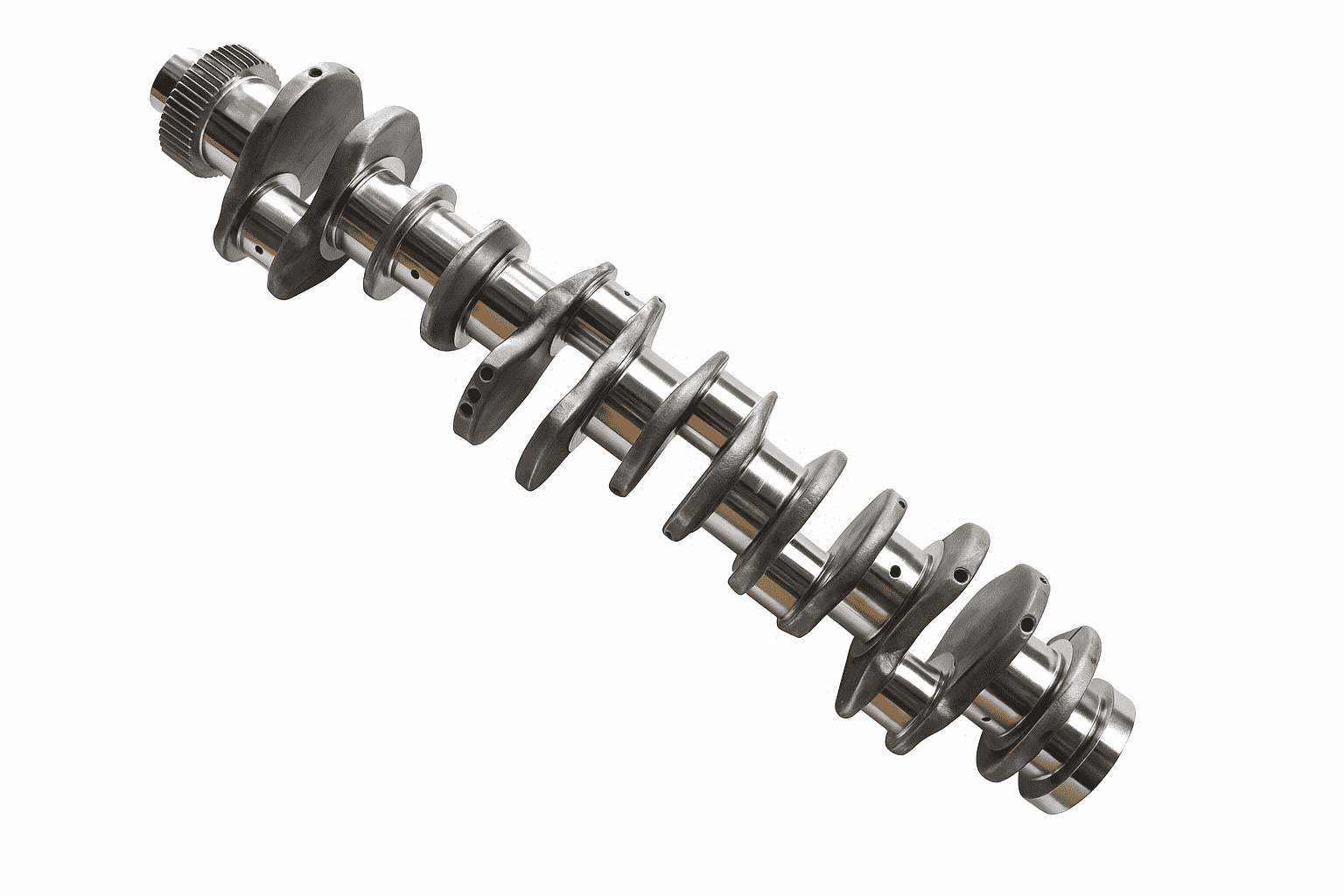

Forged Crankshafts

Closed-die forged crankshafts with heat treatment for high fatigue resistance — ideal for engines and heavy-duty power transmission systems.

- Continuous grain flow structure

- Q&T or surface treatment optional

- Finish machining available

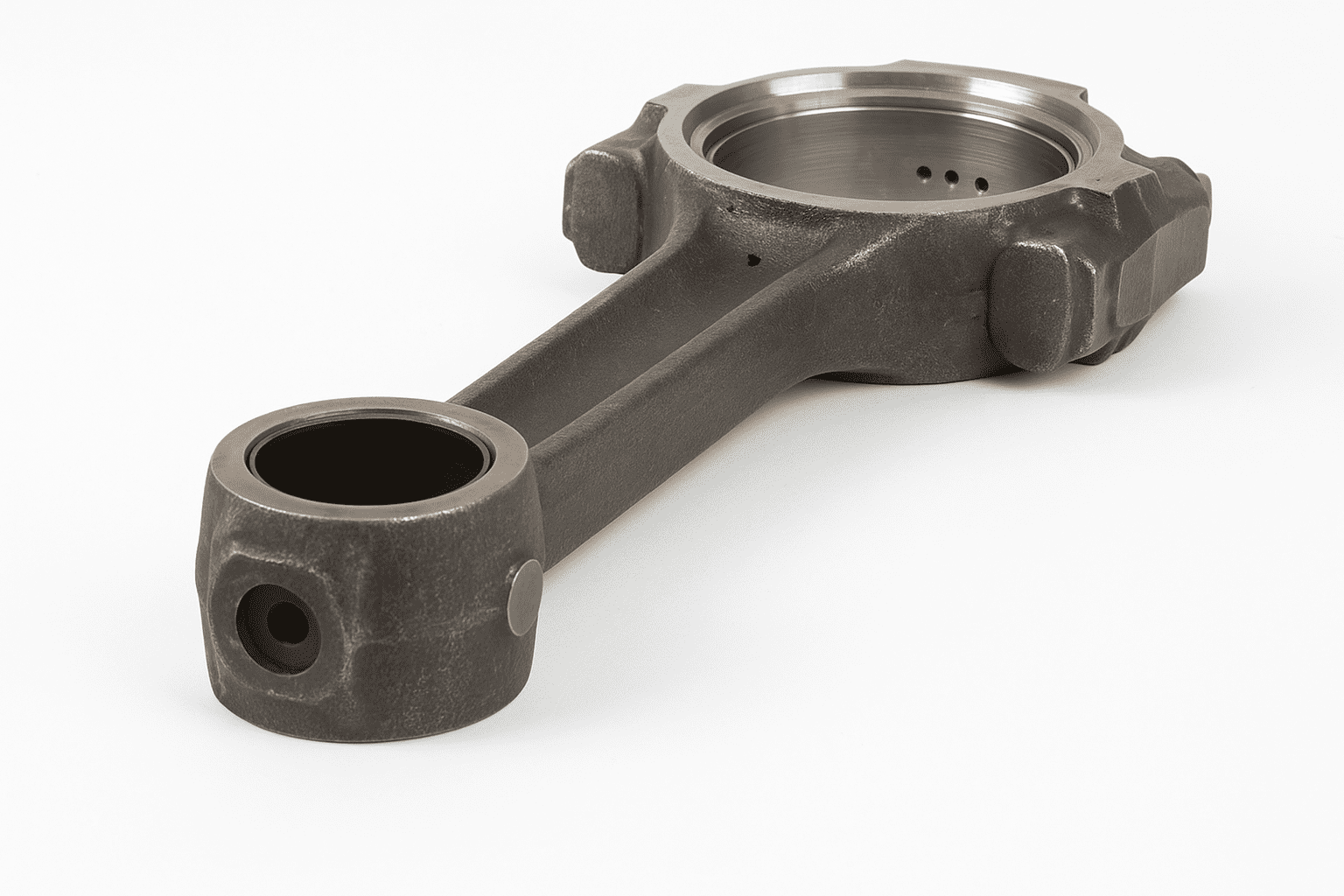

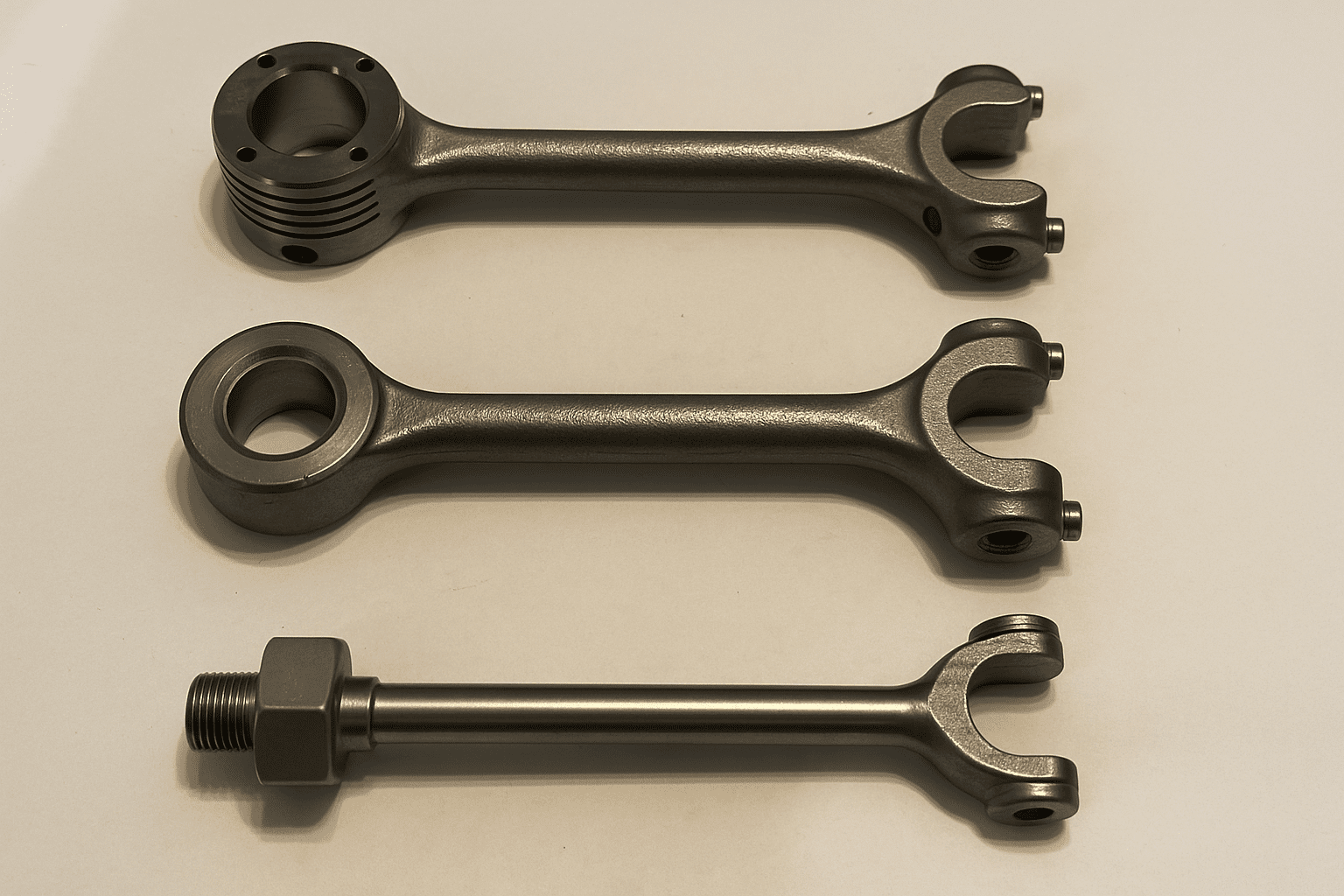

Connecting Rods & Gear Blanks

Near-net forged blanks minimizing machining stock while maintaining high strength and dimensional consistency.

- High precision & tolerance control

- Materials: 42CrMo, 20MnTi, etc.

- Applications: automotive & machinery

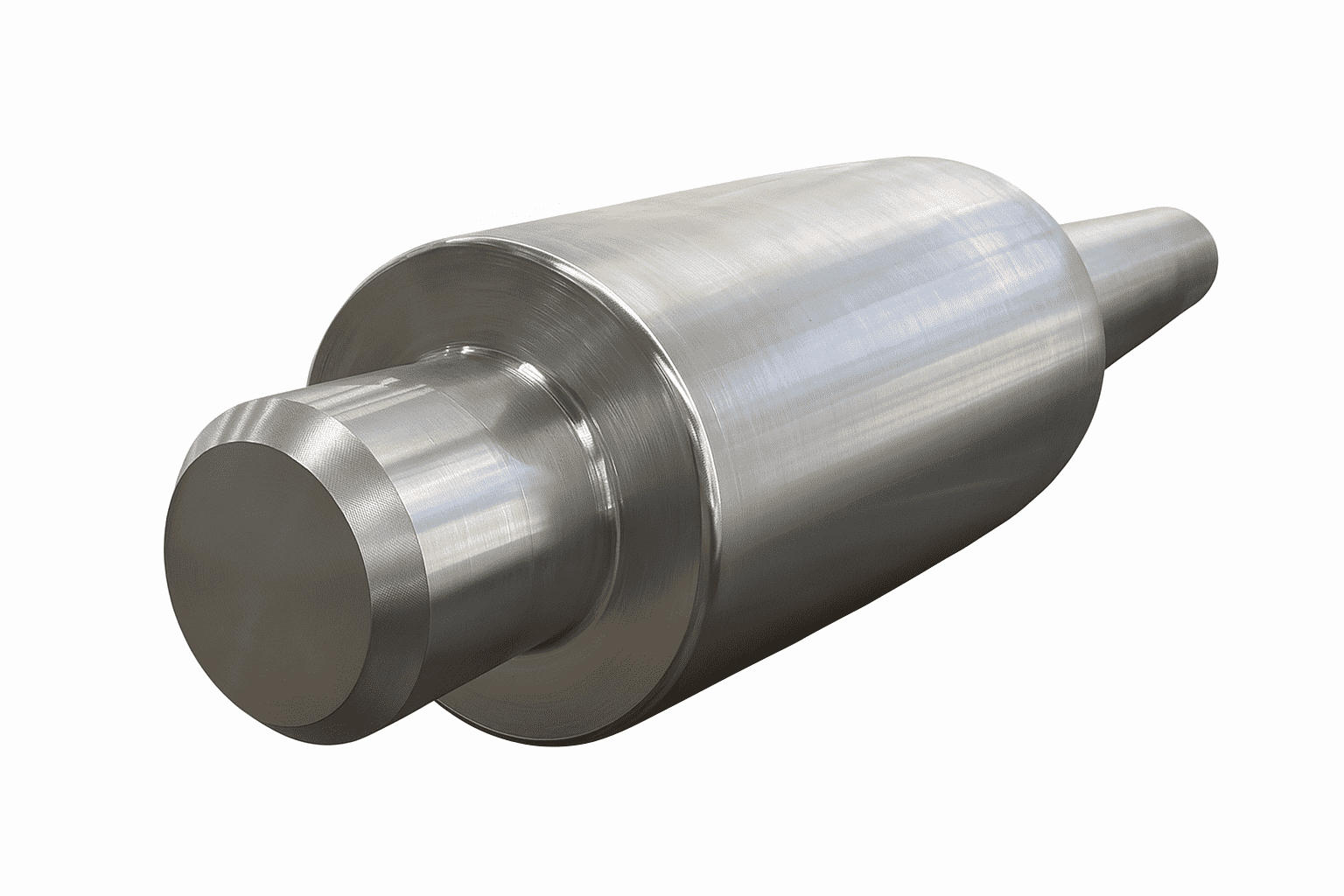

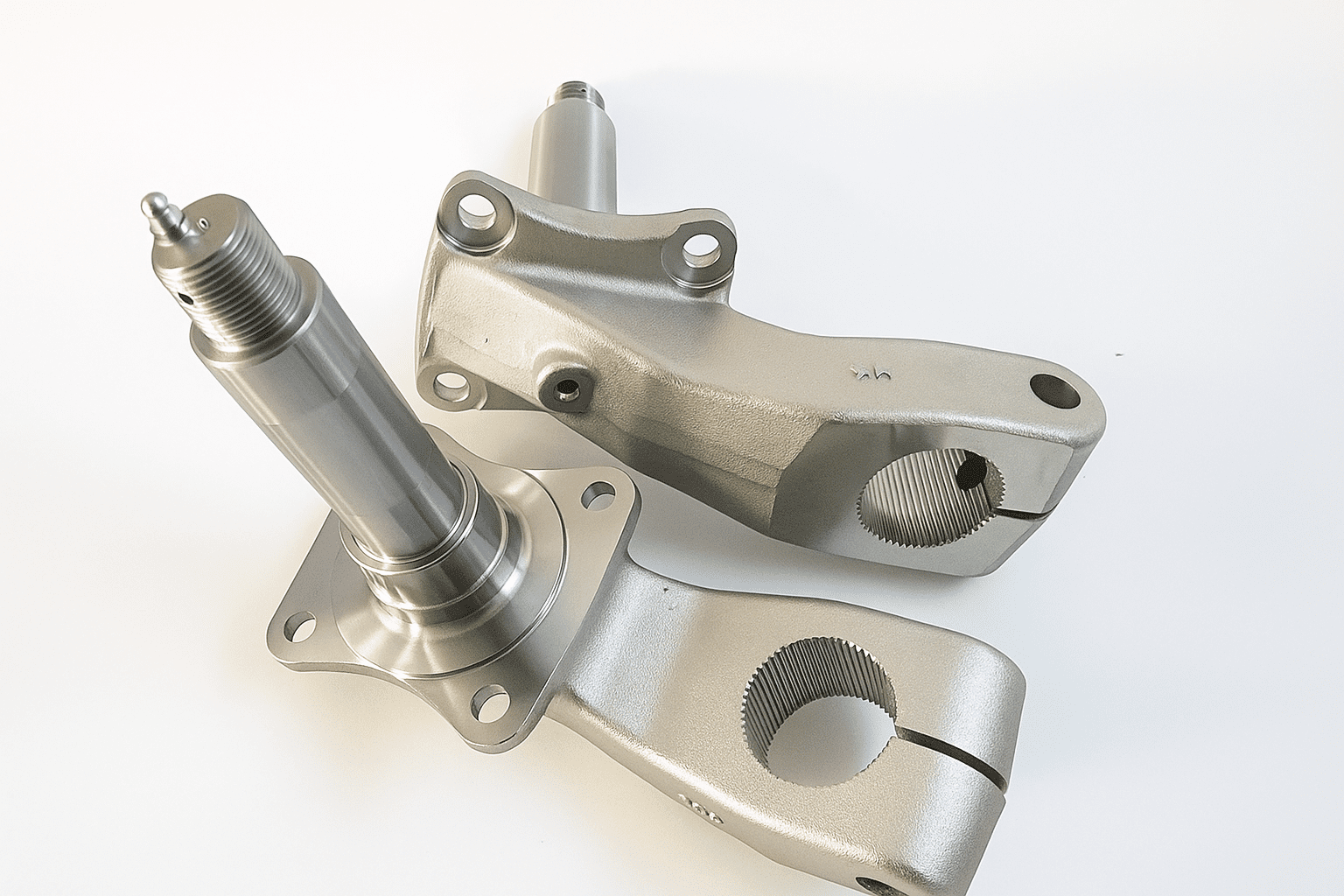

Forged Shafts

Long shafts and large-section bars produced via open-die forging for mining, power, and marine industries.

- High load-bearing & torque capacity

- Excellent fiber flow orientation

- UT/MT testing available

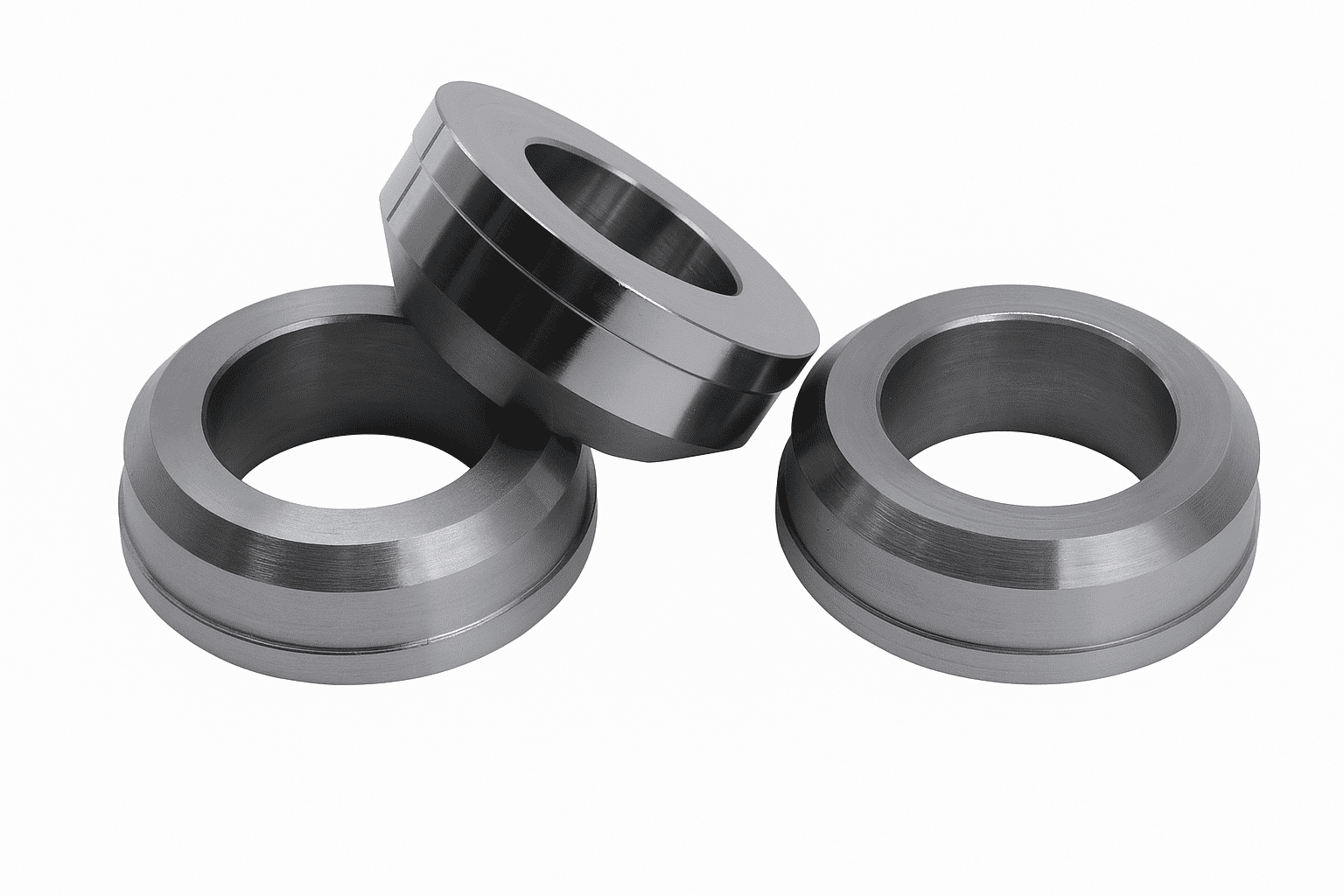

Rolled Rings

Precision ring-rolled forgings with dense structure and concentric geometry for flanges, bearing races, and gears.

- Low defect rate & tight tolerances

- Excellent concentricity

- Heat treatment & machining available

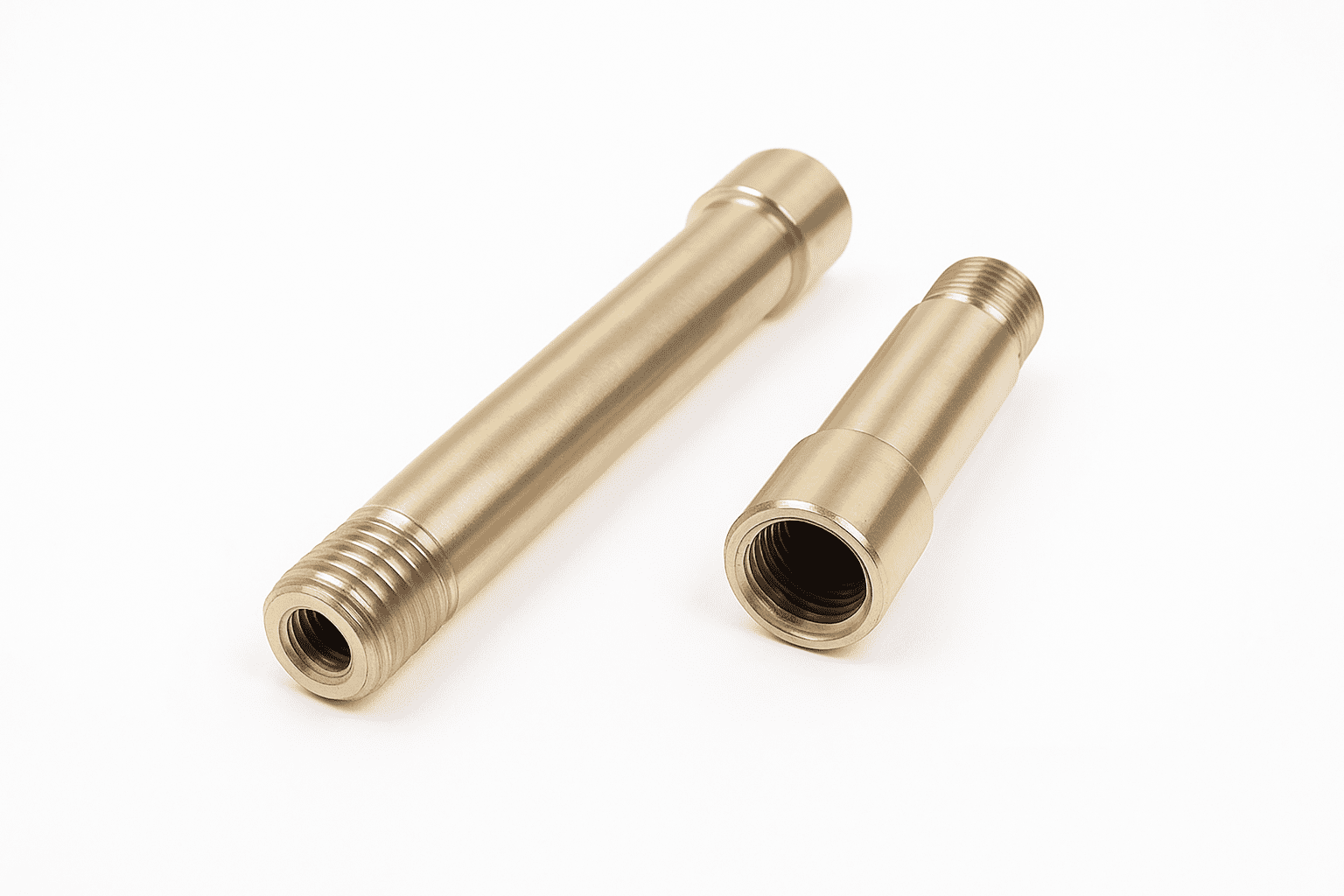

Valve Bodies & Couplings

Forged components for oil & gas and chemical pipelines — valve bodies, fittings, and couplings with reliable sealing performance.

- High-pressure & temperature resistant

- Material grades per client specs

- Custom machining available

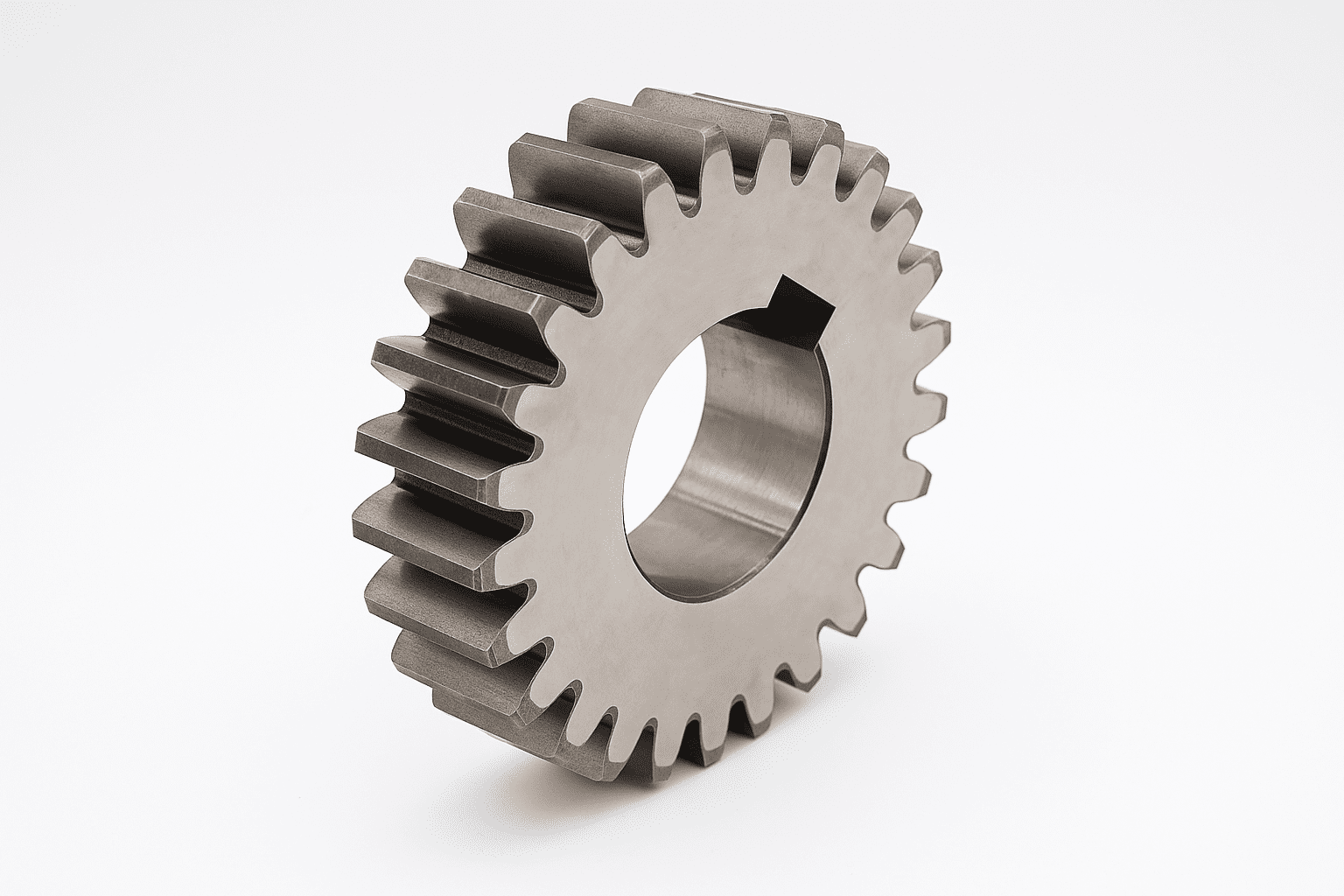

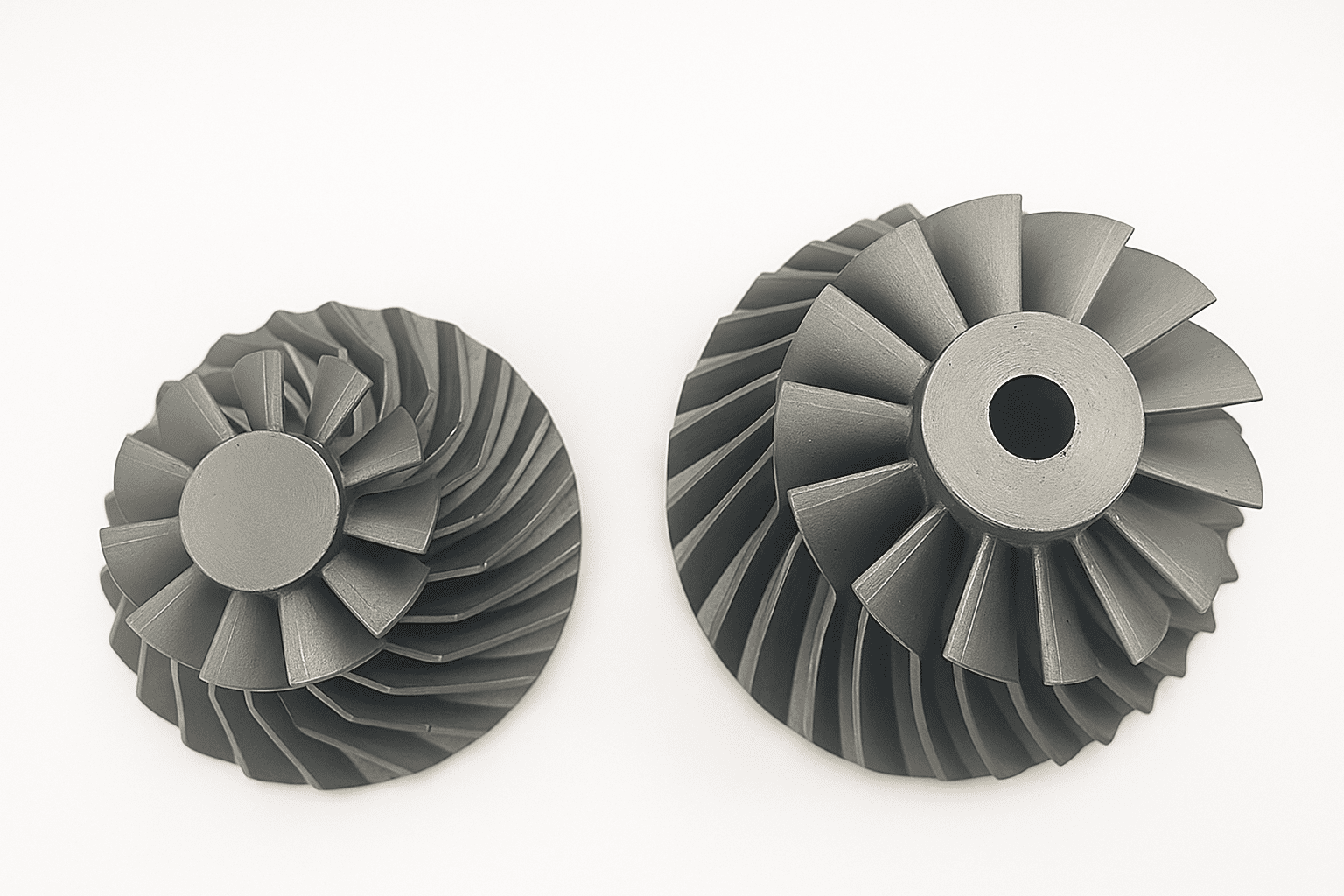

Forged Gear Blanks

Gear and spline blanks forged for transmission systems — consistent strength, hardness, and geometry.

- Batch stability & repeat accuracy

- Carburizing & Q&T optional

- Ready for finish machining

Our Forging Processes & Technical Specifications

Professional Engineering Parameter Checklist

Precision forging capability matrix covering complete technical specifications and manufacturing standards

Forging Processes

Manufacturing Methods

Press & Hammer Capacity

Equipment Tonnage

Friction Press

630T - 4000T

Electric Screw Press

1600T - 10000T

Hydraulic Hammer

2T - 10T

Forging Materials

Available Alloys

Carbon Steel

1020, 1045

Alloy Steel

4140, 4340, 8620

Stainless Steel

304/L, 316/L, 17-4PH

Aluminum Alloy

6061, 7075

Special Alloys

Titanium, Inconel

Part Weight & Dimensions

Size Specifications

We Deliver More Than Forgings — We Deliver Assembly-Ready Precision Parts

From billet to finished component, we provide an integrated one-stop service that ensures full quality control and technical optimization at every stage, delivering precision-forged parts ready for your production line.

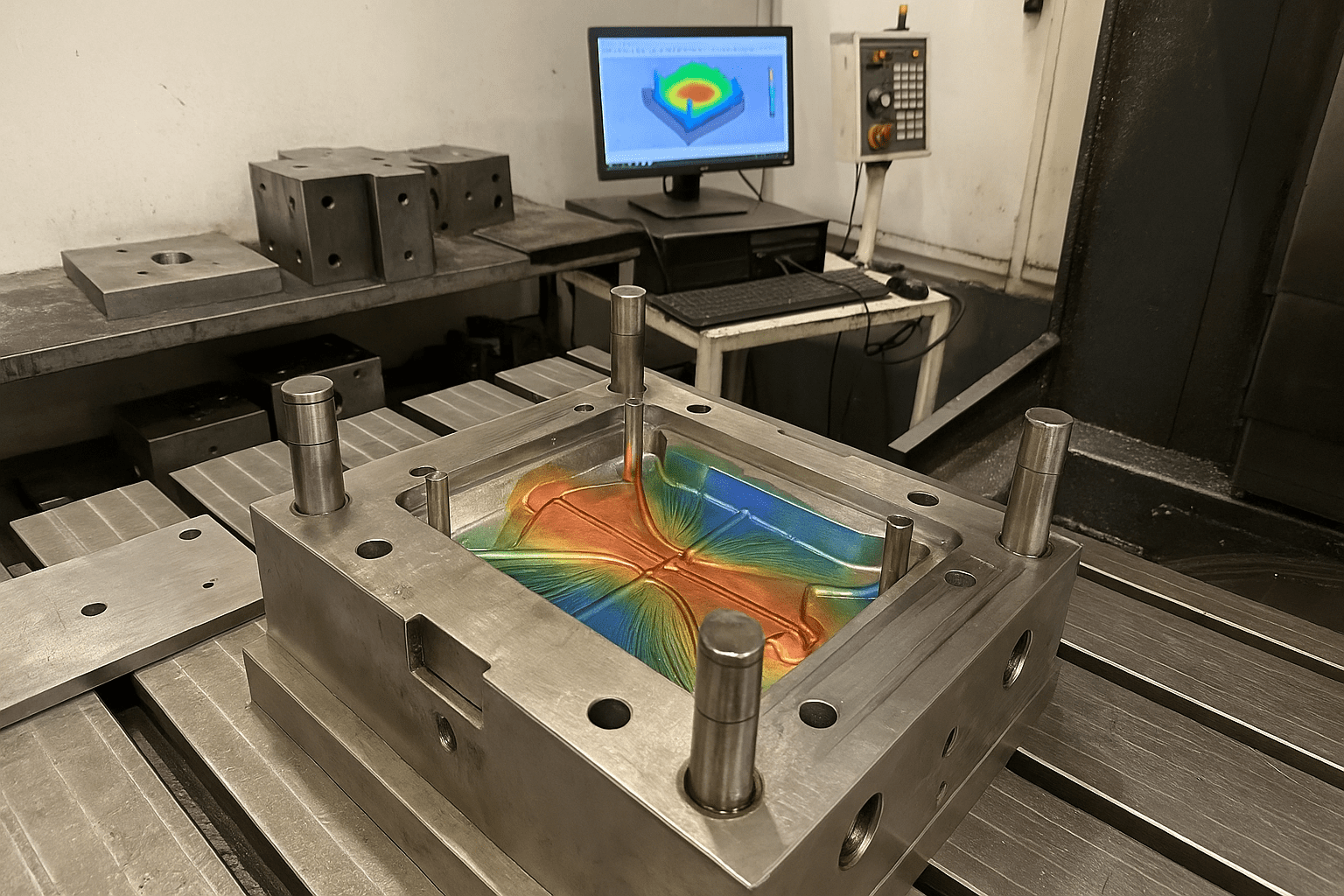

Tooling Design & Manufacturing

Using advanced CAE simulation software to optimize metal flow lines, and manufacturing tooling in our in-house CNC mold workshop to ensure first-shot success and superior mechanical performance.

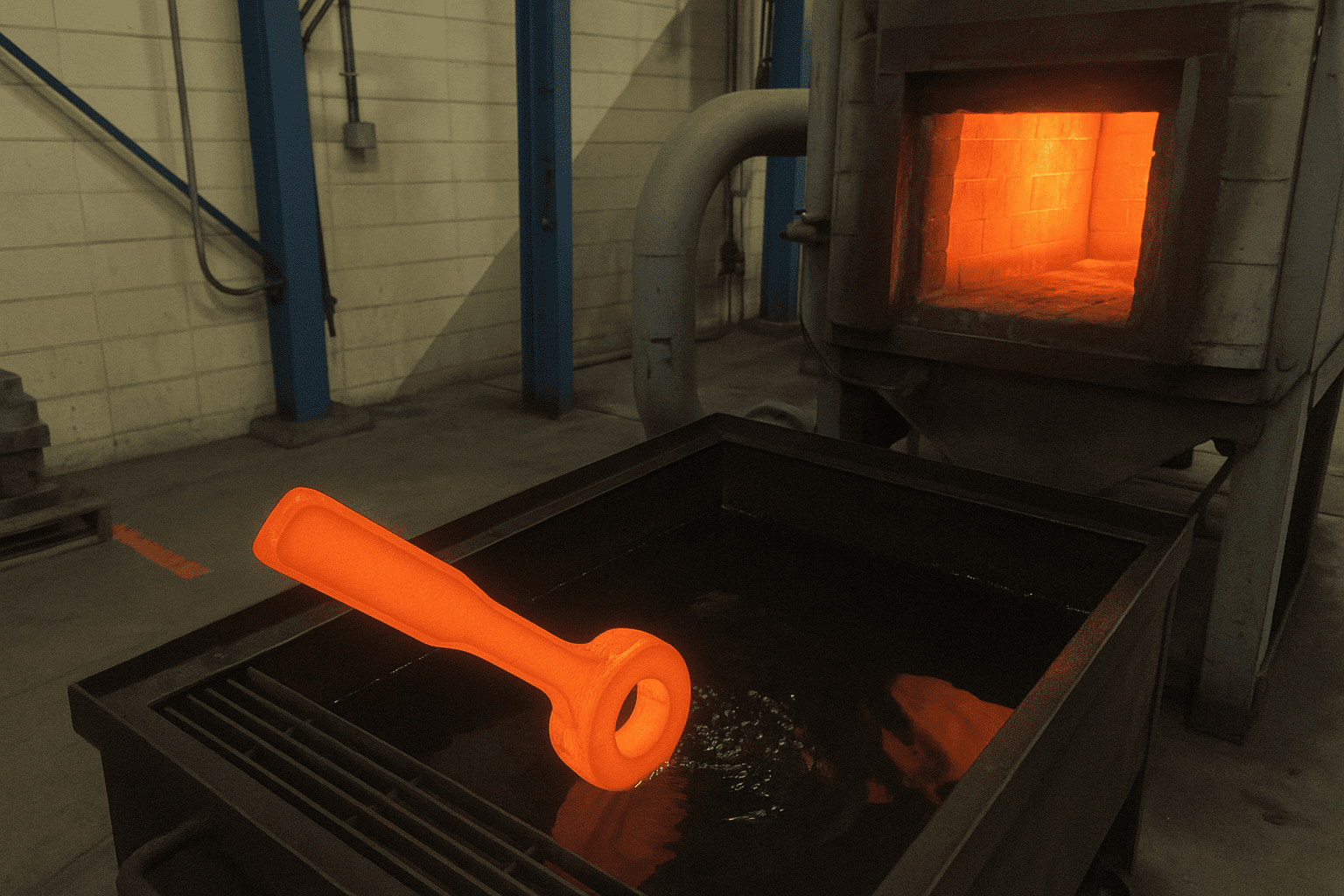

Heat Treatment

NADCAP-certified workshop offering normalizing, quenching & tempering, solution treatment, and aging, with precise control of final hardness, strength, and toughness.

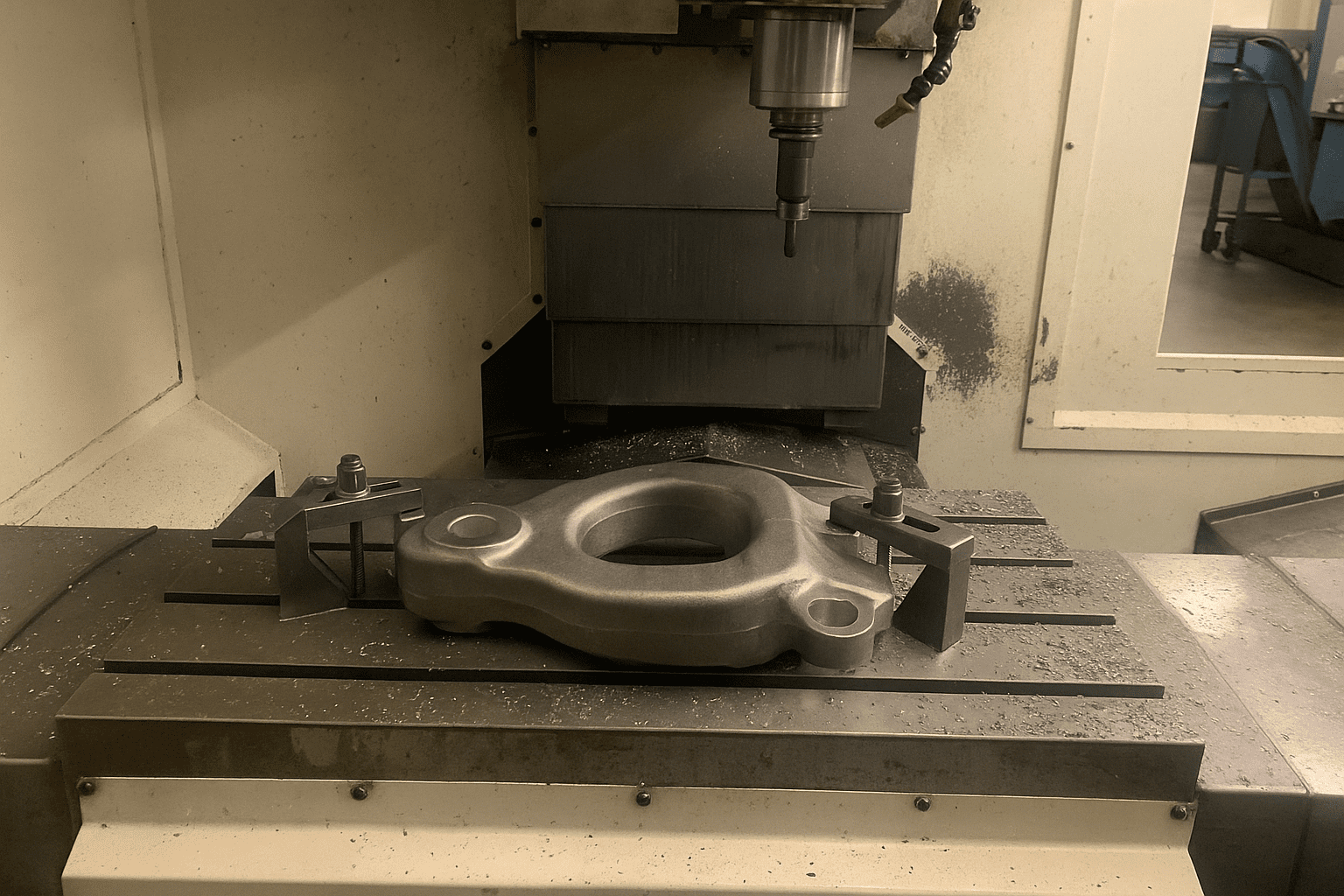

Precision Machining

From 3-axis to 5-axis machining capabilities, we handle all post-forging features, delivering near-net or finished parts with ±0.01mm tolerance.

NDT & Laboratory Testing

100% of critical components undergo magnetic particle and ultrasonic testing. Our in-house metallurgical lab conducts chemical composition analysis, mechanical property testing, and metallographic inspection to issue full material certification reports.

One-Stop Solution from Raw Material to Precision Product

30 years of expertise, 10 production lines, and ISO-certified quality management system — delivering assembly-ready forged components with guaranteed precision.

Precision Forging Excellence

From raw materials to finished components, our 10-step manufacturing process ensures exceptional quality, precision, and reliability in every forged part we deliver.

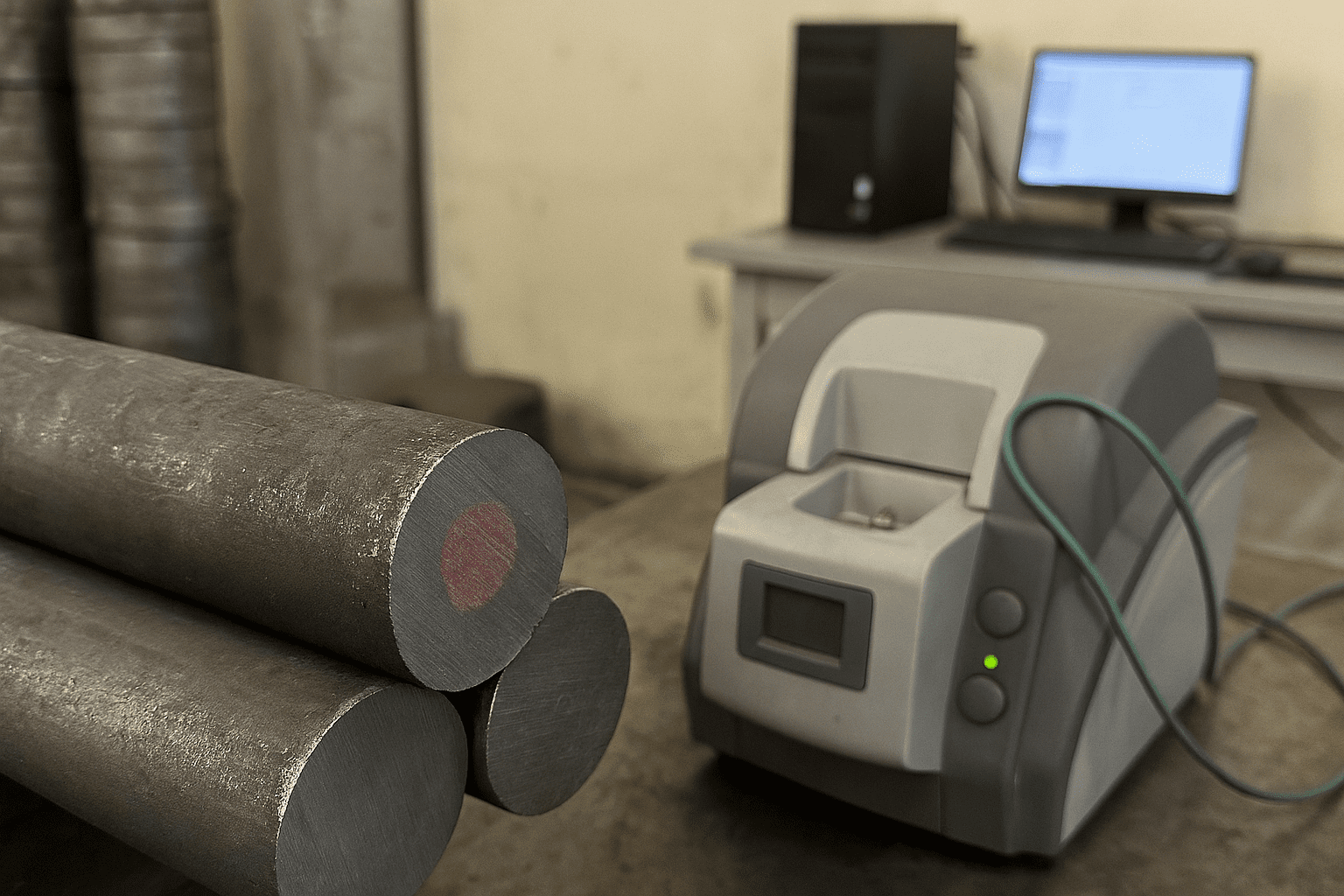

Raw Material Preparation

Raw material preparation

The process begins with the selection of high-quality raw materials such as carbon steel, alloy steel, stainless steel, or aluminum alloy. Each batch is tested for chemical composition, cleanliness, and internal defects using ultrasonic inspection and spectrometer analysis.

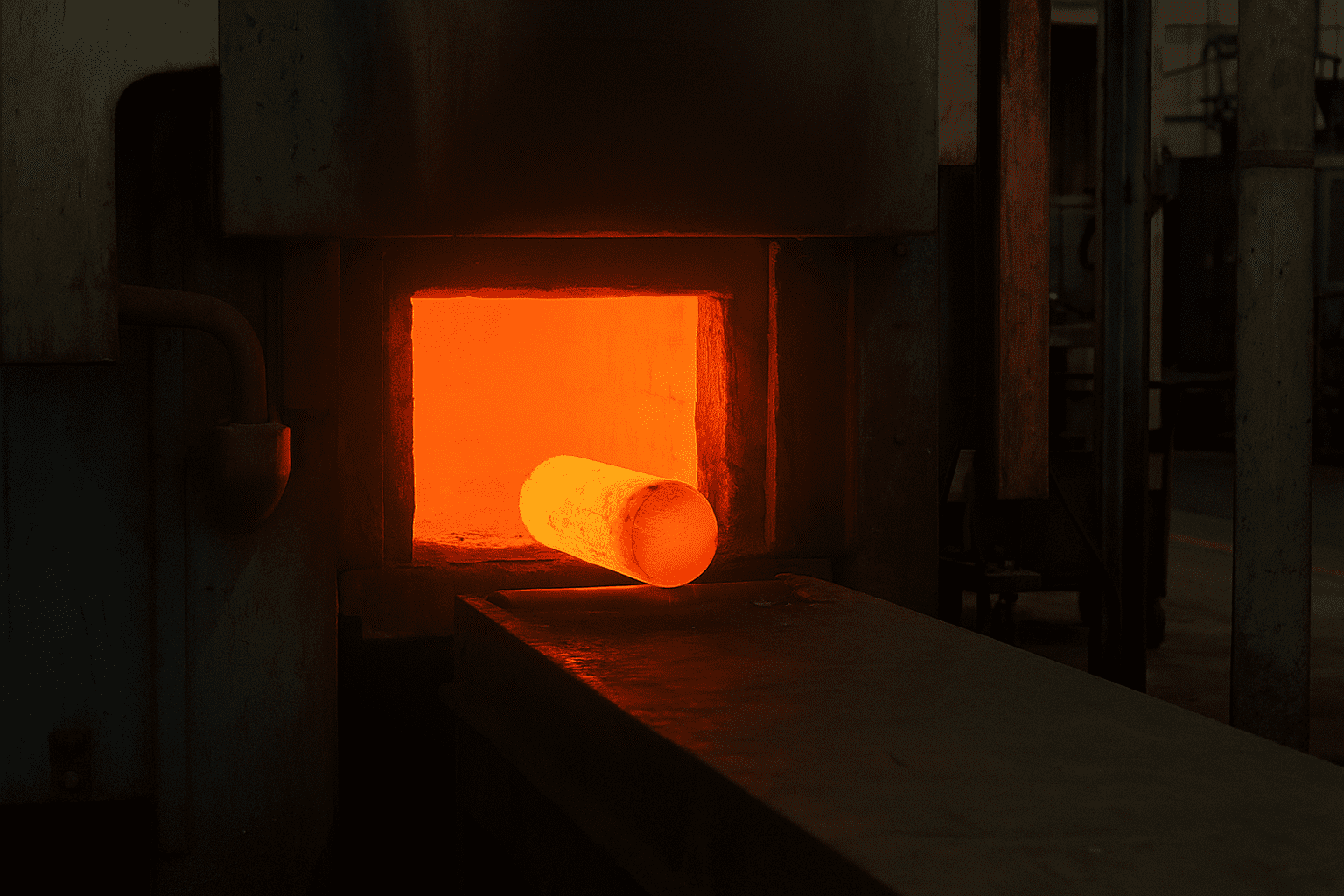

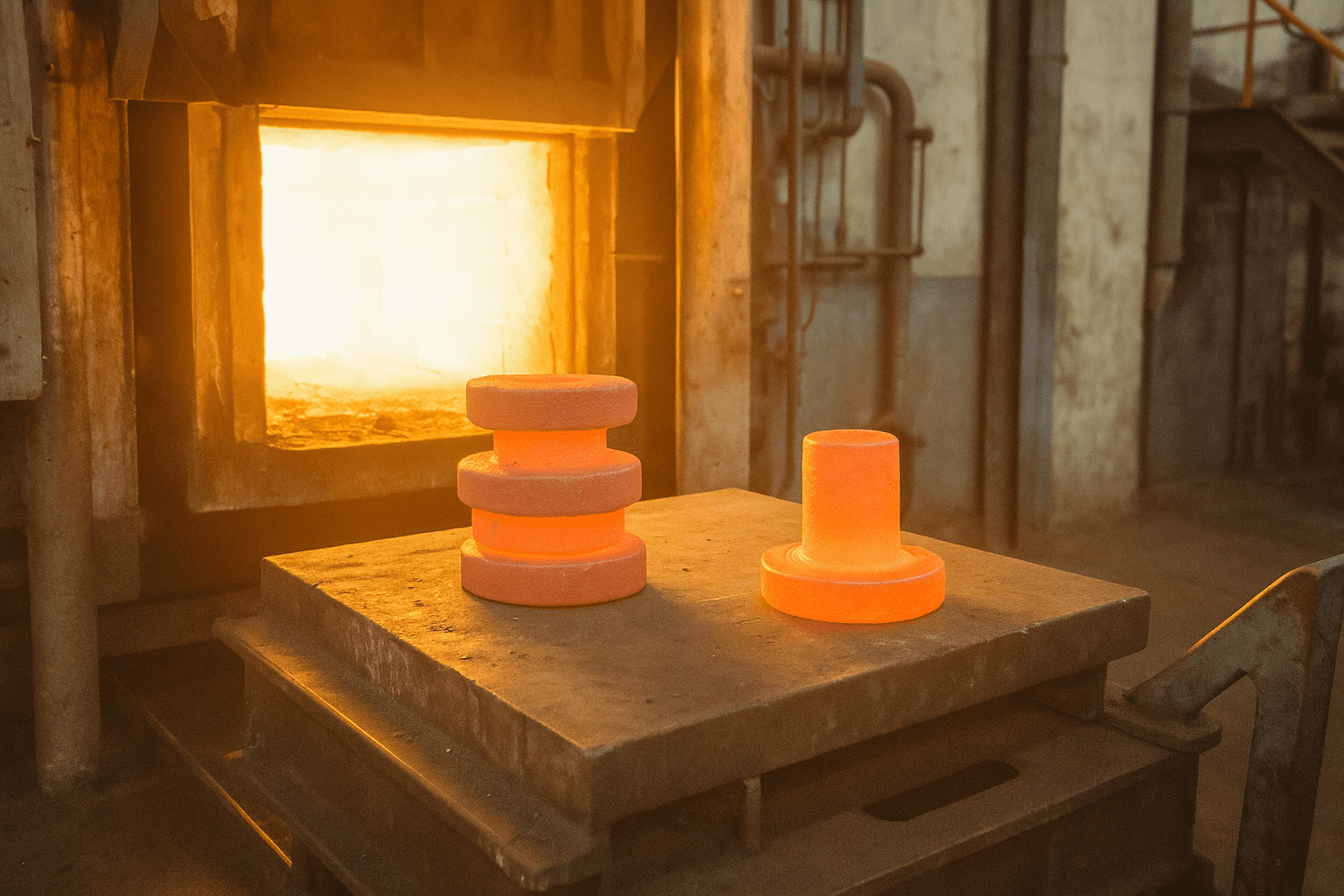

Heating

Heating

Billets are heated in an induction or gas furnace to the forging temperature range, typically between 1000°C and 1250°C. Temperature uniformity is critical to prevent cracks and uneven deformation during forging.

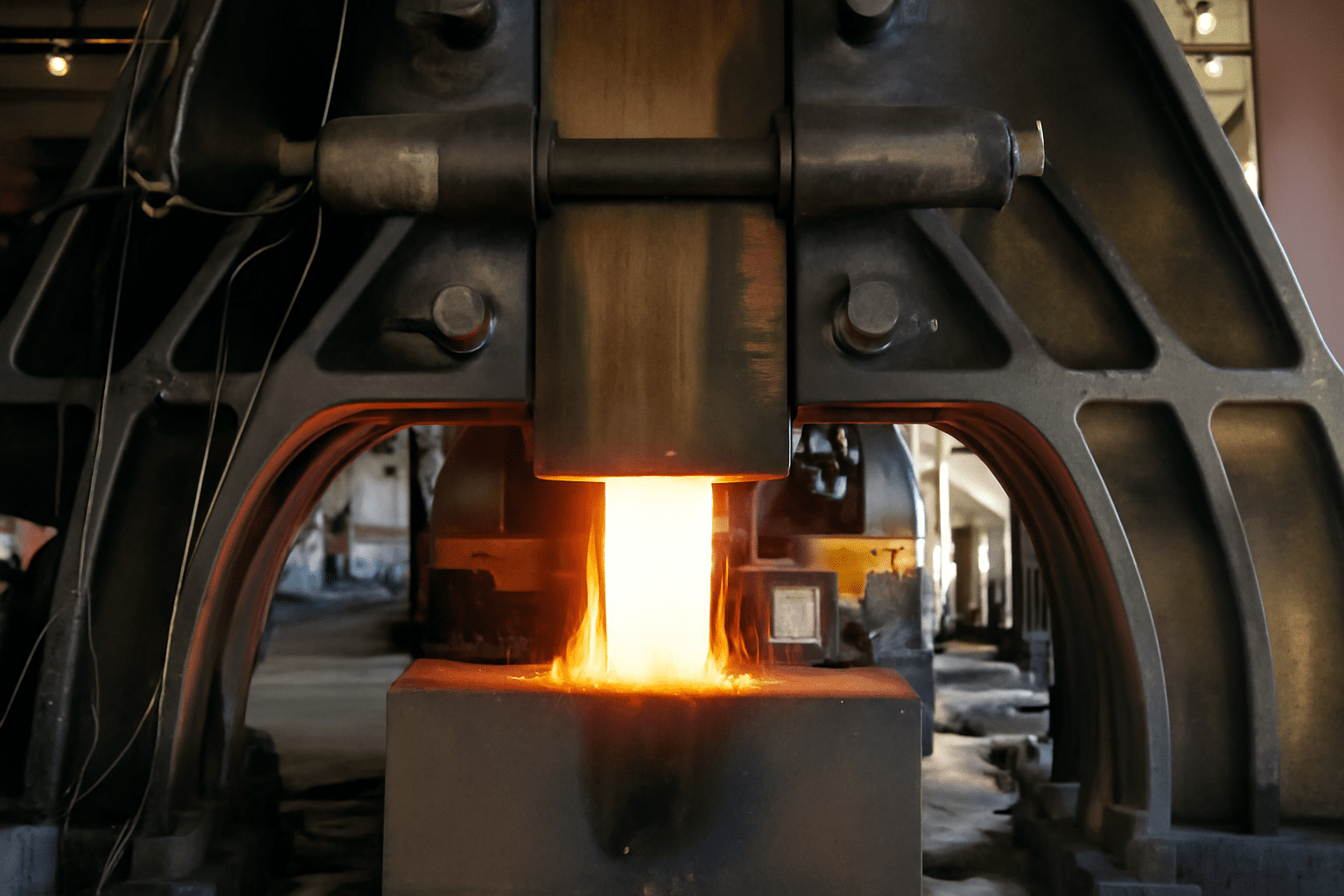

Forging & Forming

Forging and forming

Once the billet reaches the correct temperature, it is transferred to the press or hammer for deformation. Depending on product type, open-die, closed-die, or precision forging may be used. Forging refines the grain structure and enhances strength and fatigue resistance.

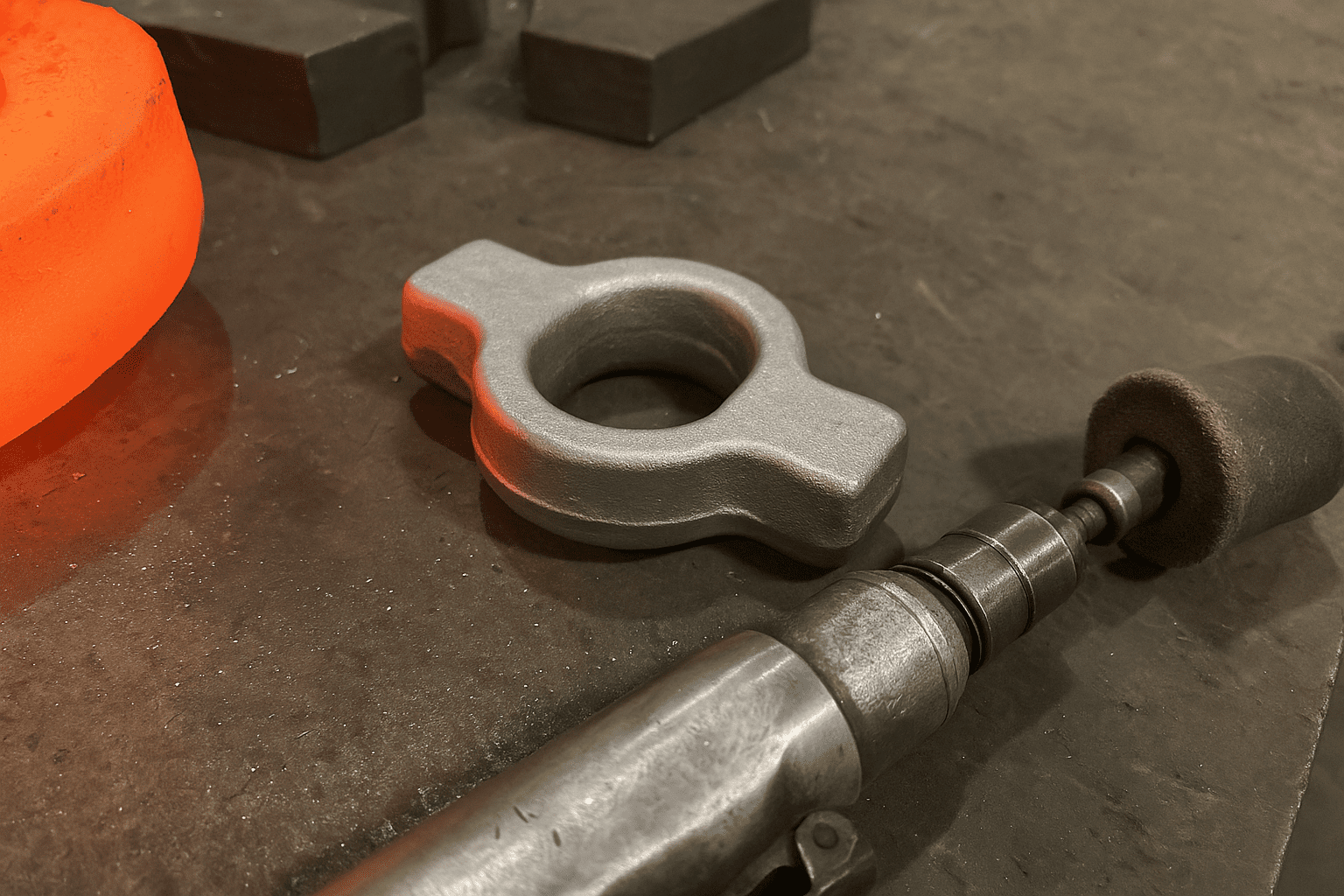

Flash Trimming & Deburring

Trimming and deburring

After forging, excess material (flash) is removed using trimming dies. Burrs and edges are then ground off to ensure dimensional accuracy and smooth transitions between part surfaces.

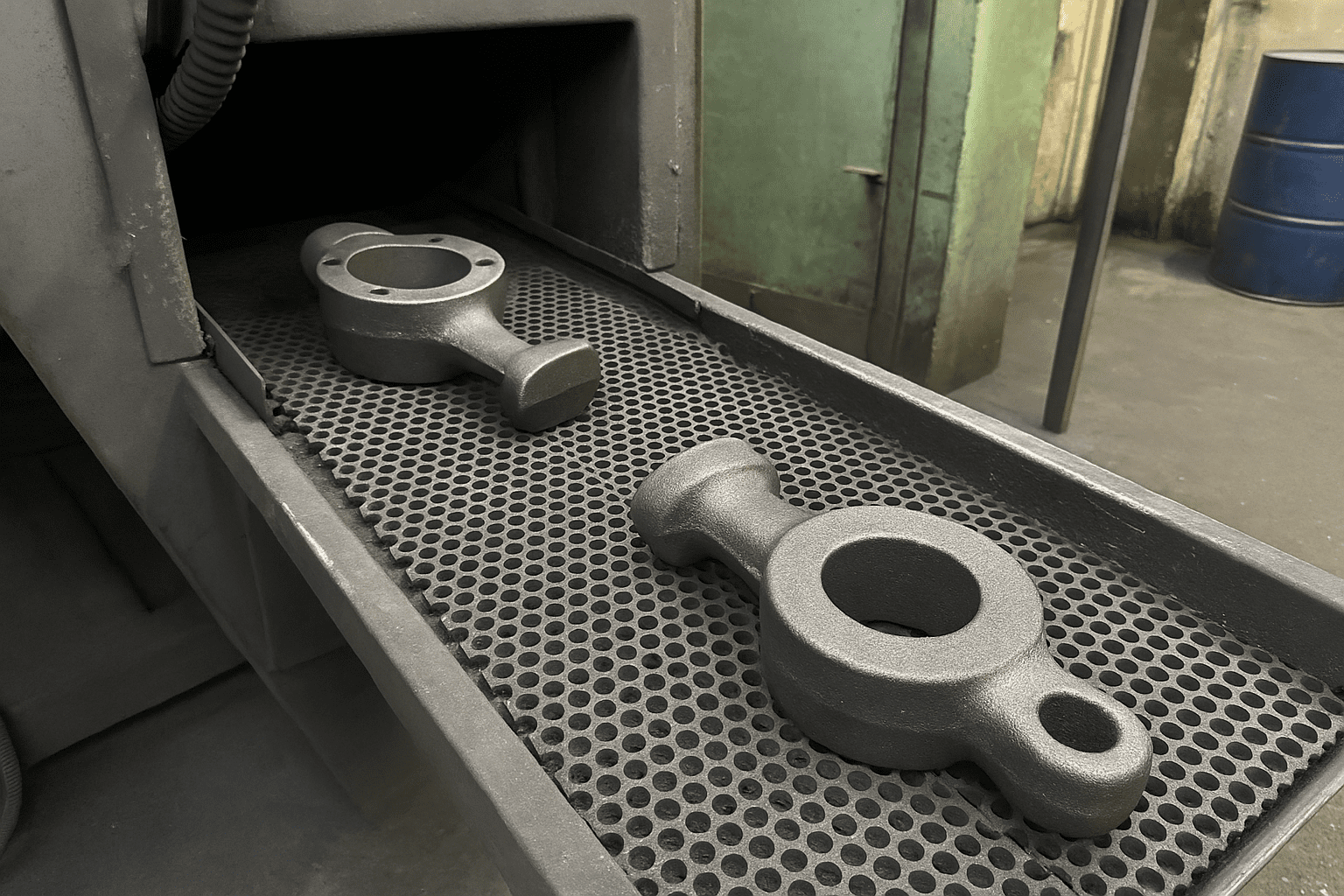

Shot Blasting & Surface Cleaning

Scale removal & surface prep

Remove scale and oxide after forging & trimming to protect tools and reveal surface defects. Clean surfaces improve subsequent machining accuracy and coating adhesion.

Pre-Heat-Treat Machining (Roughing)

Establish datums & remove allowance

Perform necessary rough turning/milling/drilling to set machining datums, straighten features, and remove forging allowance. This reduces distortion impact during heat treatment.

Heat Treatment

Normalize / Q&T / Solution + Age

Apply controlled heat treatment to achieve target mechanical properties. Roughing beforehand minimizes post-HT stock and improves dimensional stability for finishing.

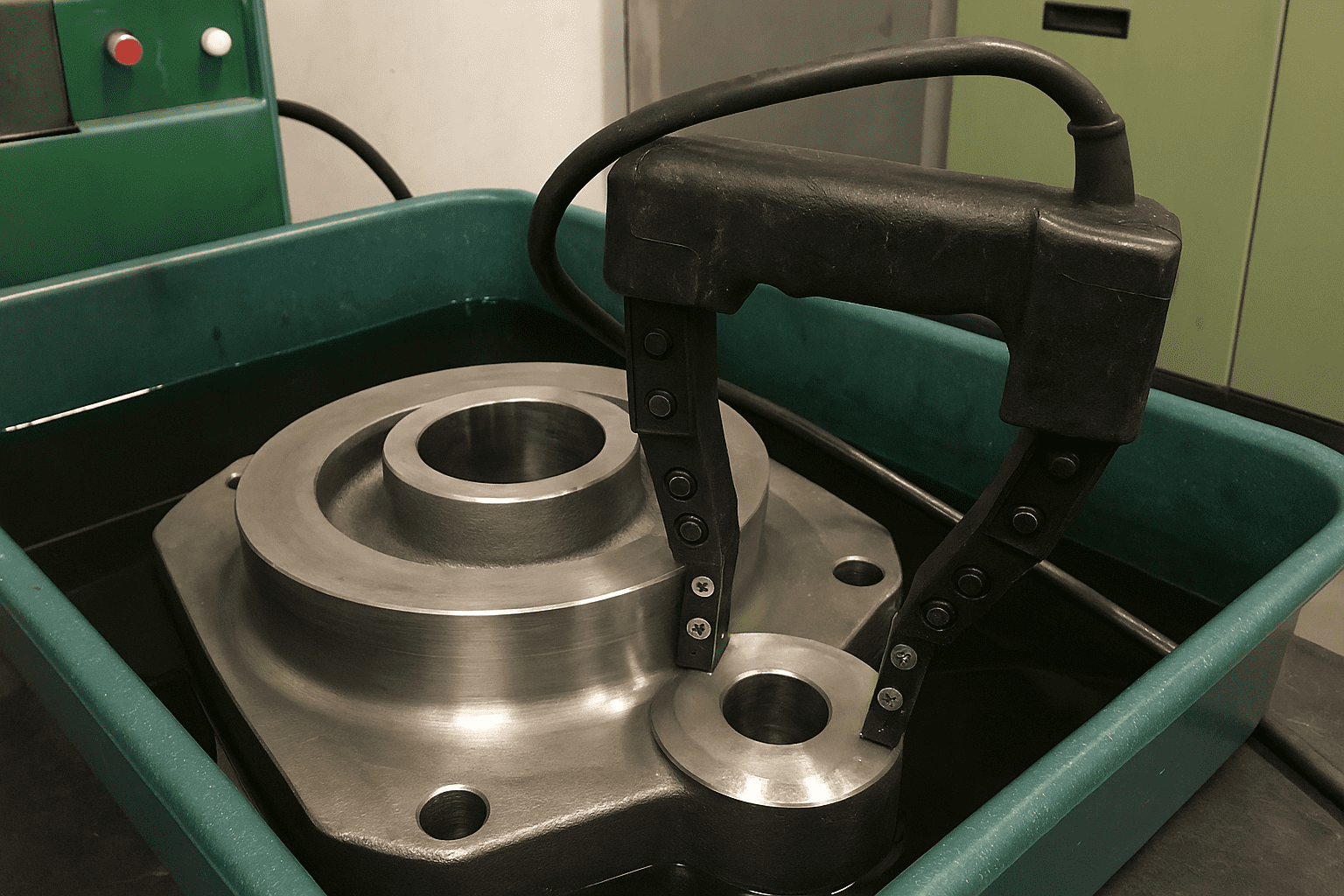

Non-Destructive Testing (NDT)

MPI / UT / PT

Conduct NDT after heat treatment to reveal quench-related cracks and internal defects before final finishing.

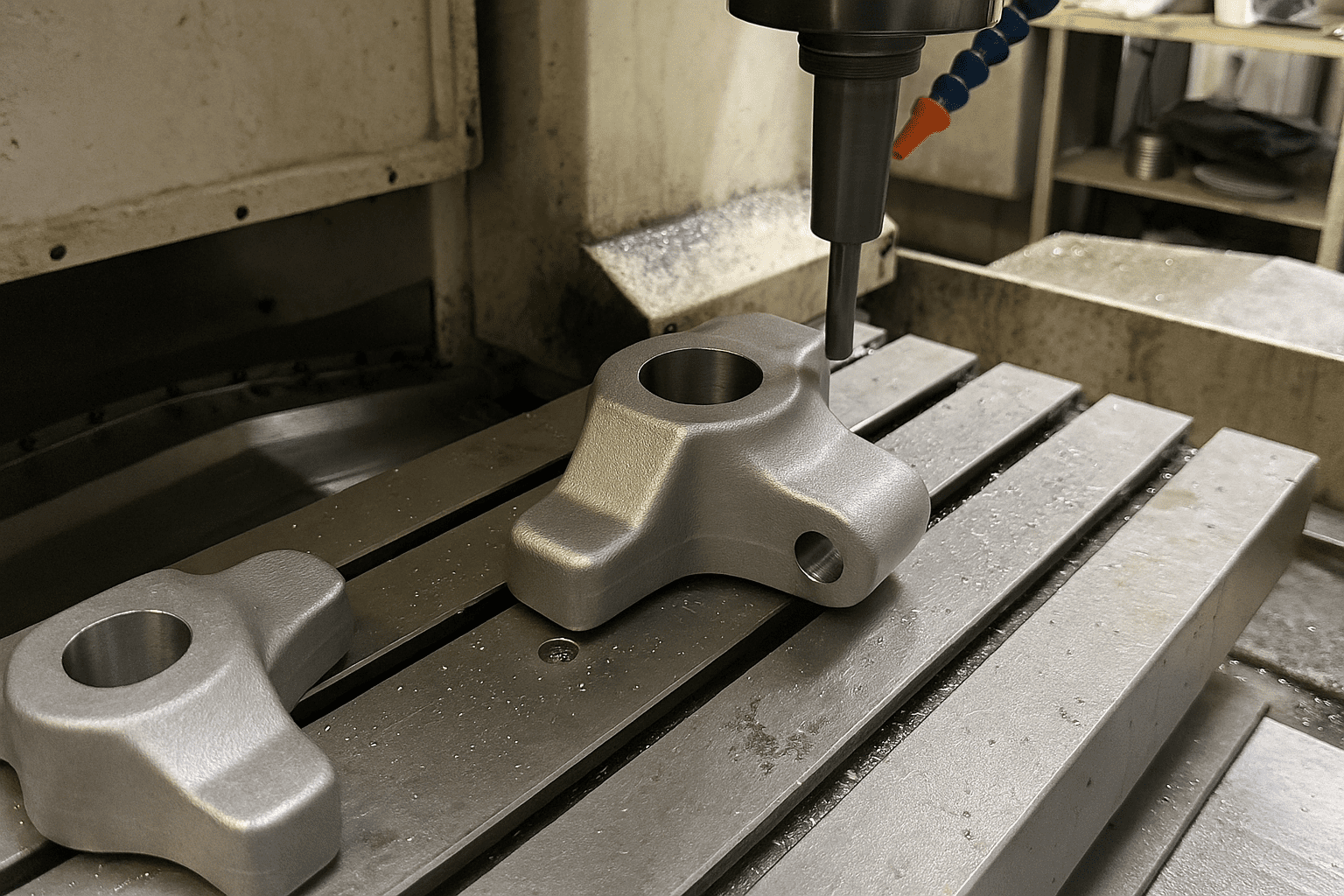

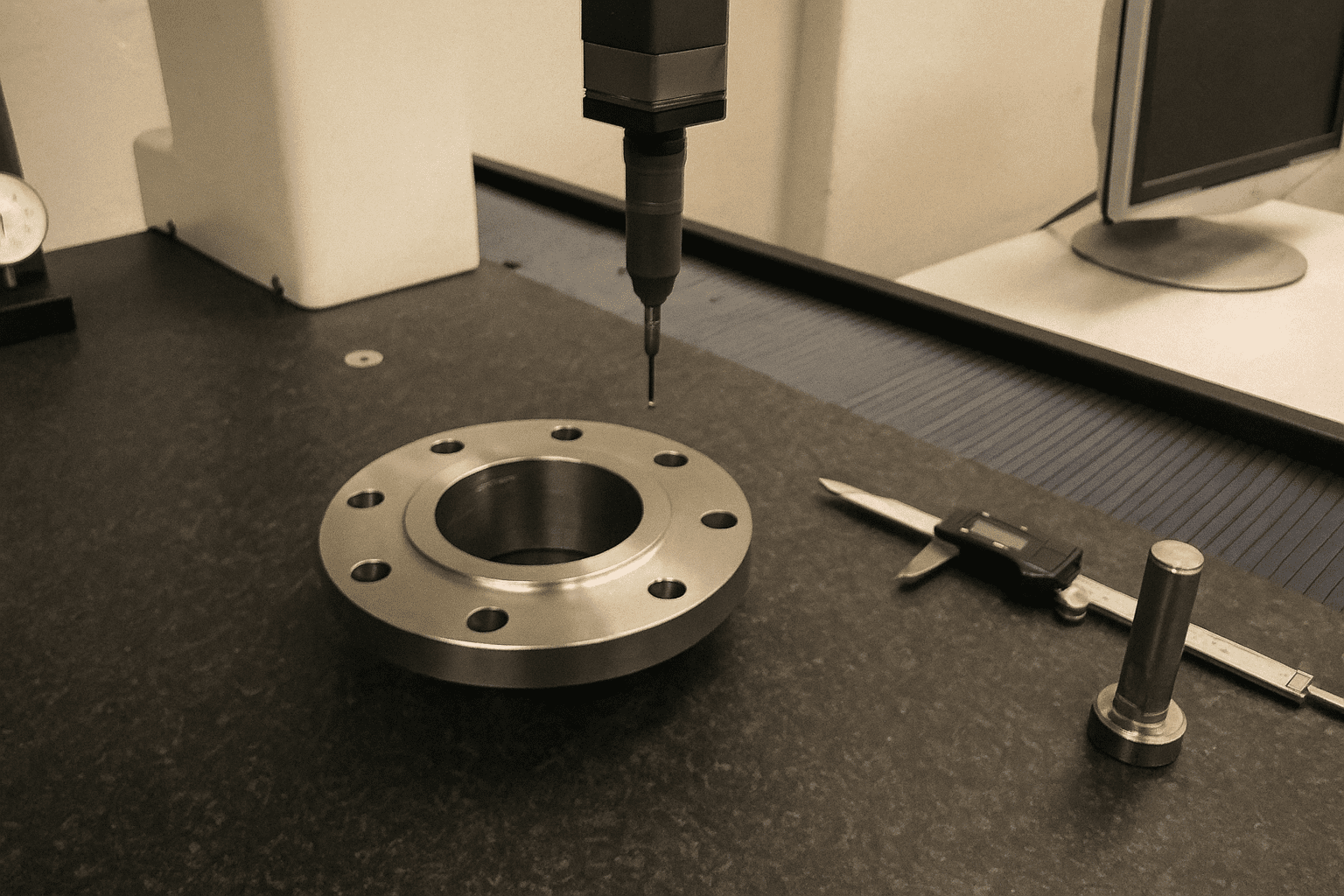

Finish CNC Machining & Final Dimensional Check

Tight tolerances after HT

Perform finish turning/milling/grinding to reach final tolerances (up to ±0.01 mm), followed by full CMM verification against drawings and CTQs.

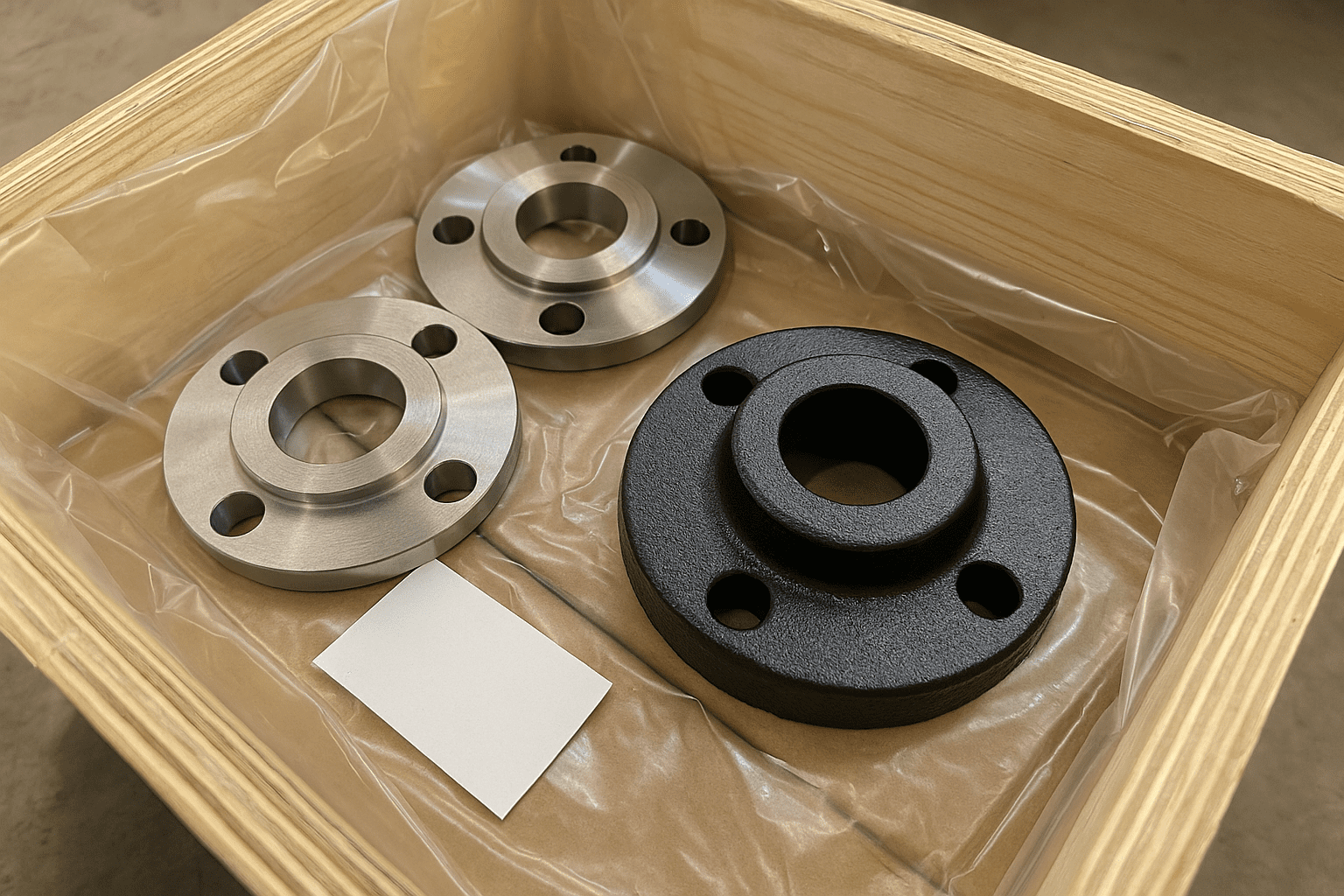

Surface Treatment & Packaging

Surface treatment and packaging

Surface finishes such as zinc plating, black oxide, painting, or phosphating are applied per customer requirement. Parts are then rust-proofed, labeled, and packaged in export-grade cartons or wooden crates.

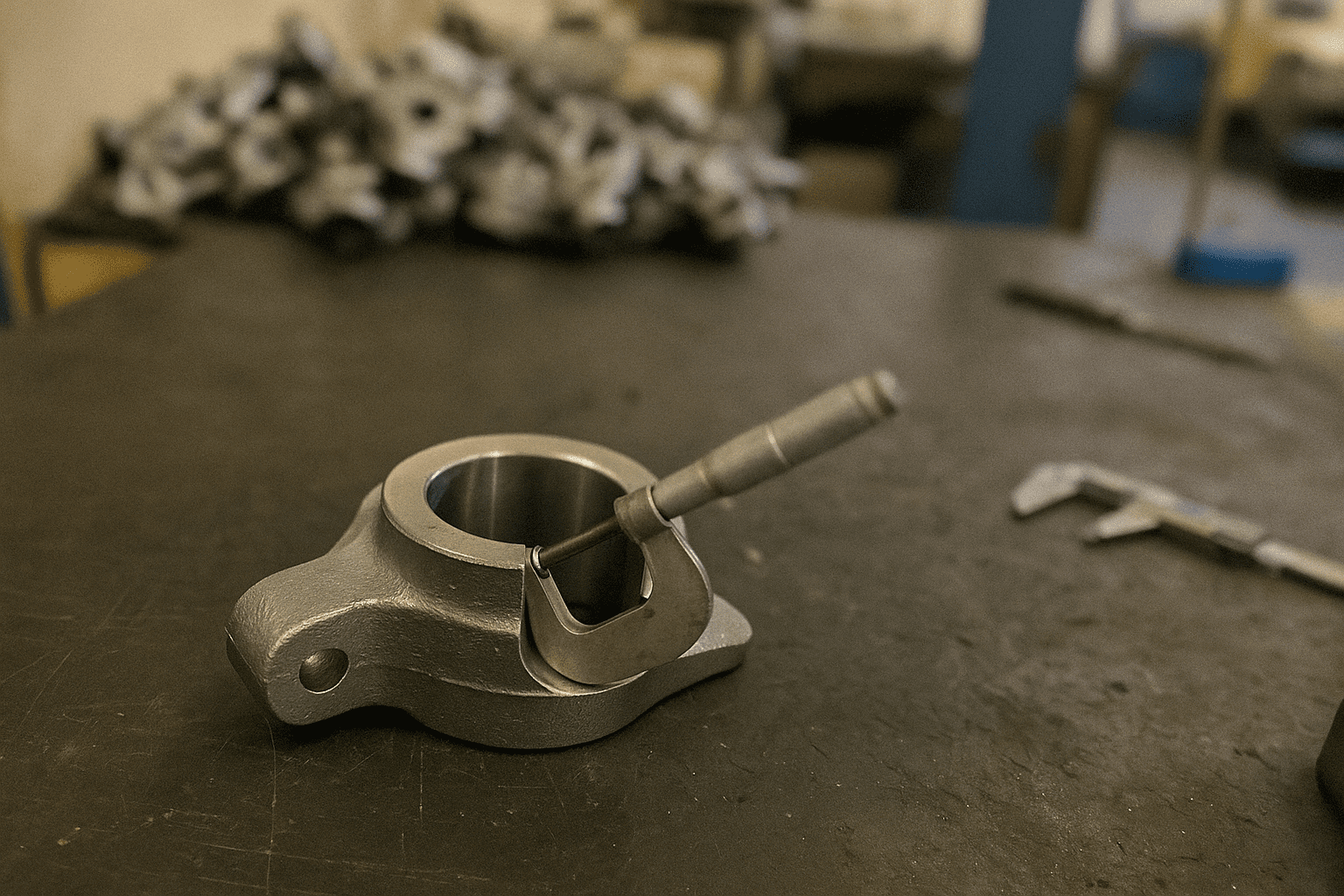

Complete Quality Assurance

A professional forging parts manufacturer controls every stage — from material selection to final inspection — ensuring parts meet ISO 9001 and industry standards for durability and precision.

Powering Global Leaders with Critical Safety & Performance

Our precision forging expertise delivers mission-critical components that power the world's most demanding applications, from high-performance automotive engines to aerospace safety systems.

High-Performance V8 Engine Connecting Rod

Hover to view case details

Product

Engine Connecting Rod

Material

4340 Alloy Steel

Challenge

Achieve 15% weight reduction while withstanding higher burst pressure and fatigue limits.

Solution

"Through forging flow line optimization and multi-stage heat treatment processes, we delivered connecting rods that not only passed the customer's 1 million cycle bench tests, but also maintained weight consistency within ±1 gram."

Aircraft Landing Gear Torque Arm

Hover to view case details

Product

Landing Gear Torque Arm

Material

Titanium Alloy (Ti-6Al-4V)

Challenge

Zero-defect requirement with 100% internal structural integrity.

Solution

"Using isothermal forging processes combined with 100% ultrasonic and X-ray inspection, we ensure every component meets AS9100 stringent standards with complete traceability documentation."

Marine Propeller Hub Assembly

Hover to view case details

Product

Propeller Hub Assembly

Material

Duplex Stainless Steel

Challenge

Extreme corrosion resistance in saltwater with 20-year service life requirement.

Solution

"Specialized marine-grade forging with controlled grain structure and post-forge passivation treatment, delivering components that exceed DNV-GL marine certification standards."

Power Generation Turbine Disc

Hover to view case details

Product

Turbine Disc Assembly

Material

Inconel 718 Superalloy

Challenge

Operating at 650°C with 30,000+ hour service life in continuous operation.

Solution

"Advanced superalloy forging with controlled cooling rates and triple-stage aging treatment, achieving creep resistance that exceeds industry benchmarks by 25%."

Ready to Engineer Your Next Critical Component?

Join industry leaders who trust our precision forging expertise for their most demanding applications.

Comprehensive Quality Testing

Prime conducts complete testing series according to international standards or customer-specified requirements. Through our ISO 9001 and ISO 17025 certified laboratory partnerships, we ensure all testing processes are traceable and results are verifiable.

Expert Analysis & Reporting

Our materials and quality specialists provide detailed analysis reports based on testing data, ensuring every forged component meets or exceeds customer performance requirements.

Mechanical Testing

Tensile Test

Strength Analysis

Testing yield strength, tensile strength, and elongation to evaluate metal plasticity and strength performance.

Hardness Test

Multiple Methods

Brinell (HBW), Rockwell (HRC/HRB), and Vickers micro-hardness (HV) testing to verify heat treatment effects.

Impact Test

Toughness Evaluation

Charpy V-Notch impact testing and low-temperature impact testing to evaluate material toughness.

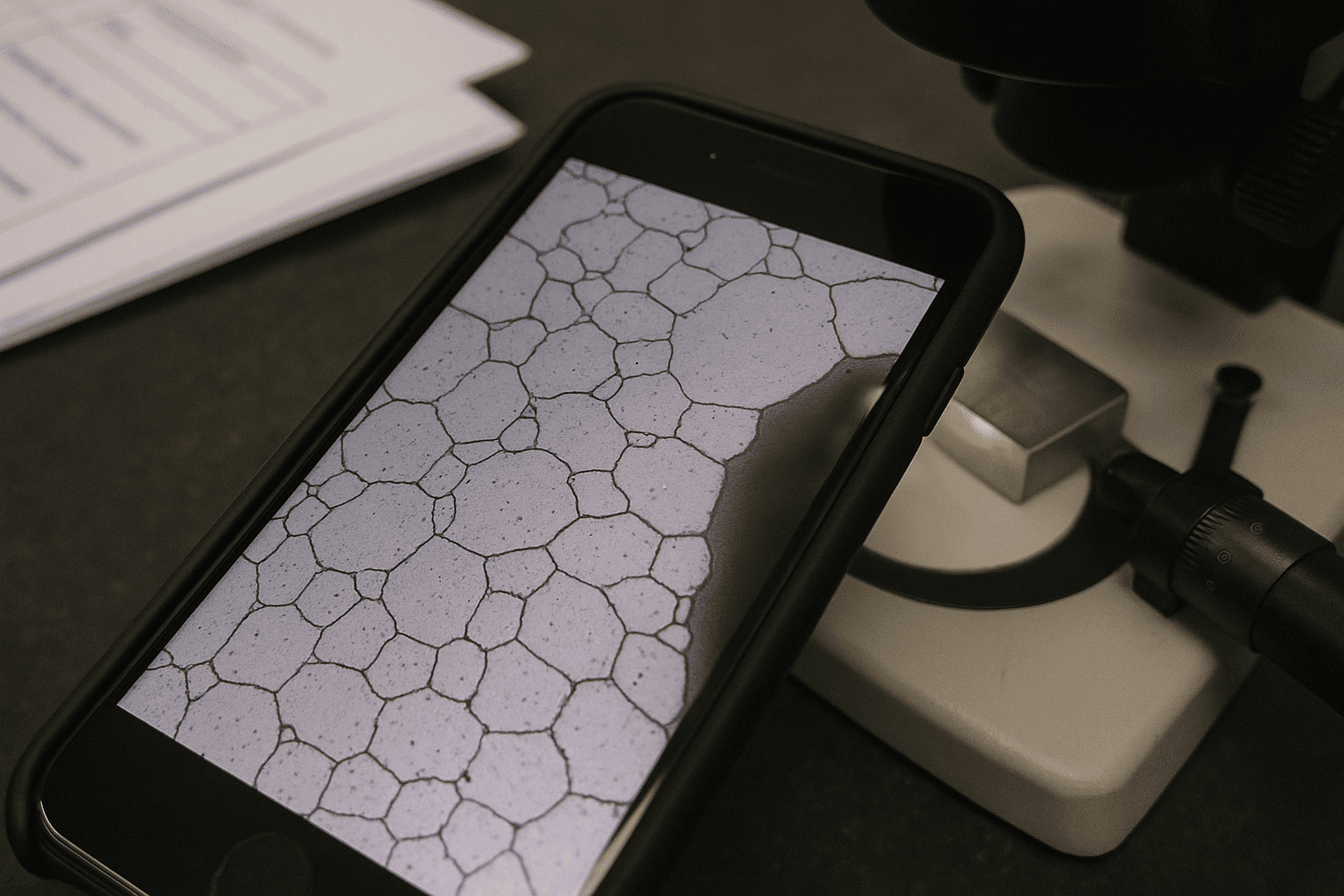

Metallographic Analysis

Microstructure Examination

Analysis of grain size, phase distribution, decarburization layer, and inclusions for optimal material properties.

Macrostructure Inspection

Examination of flow lines, forging defects, porosity, and segregation patterns in forged components.

ASTM Standard Compliance

Grain size and inclusion rating according to ASTM E112 and E45 standards with detailed documentation.

Non-Destructive Testing (NDT)

Ultrasonic (UT)

Internal crack, porosity, and inclusion detection

Magnetic Particle (MT)

Surface and near-surface defect identification in ferromagnetic materials

Penetrant (PT)

Crack detection for non-magnetic materials

X-Ray (RT)

Internal defect radiographic inspection for critical sections

All NDT performed by ISO 9712 certified inspectors with traceable reporting

Corrosion Testing

Intergranular Corrosion (ASTM A262)

For austenitic stainless steel, verifying resistance after welding or heat treatment.

Pitting & Crevice Corrosion (ASTM G48)

Evaluating localized corrosion performance of stainless steel and nickel alloys.

Duplex Steel Stability (ASTM A923)

Detection of harmful intermetallic precipitation in duplex stainless steels.

Chemical Analysis

Optical Emission Spectroscopy (OES)

Rapid alloy composition and deviation detection

Combustion Analysis (LECO)

C, S, N, O content measurement for high-purity materials

X-Ray Fluorescence (XRF/PMI)

Raw material identification and incoming inspection

Our Commitment

Prime's testing system covers the complete process from raw materials through heat treatment to mechanical properties and corrosion resistance. Every test is built on ISO standards and customer technical specifications.

Stable & Traceable

Material composition stability with full traceability

Uniform Performance

Consistent microstructure and mechanical properties

100% Inspection

Every shipped component passes complete quality inspection

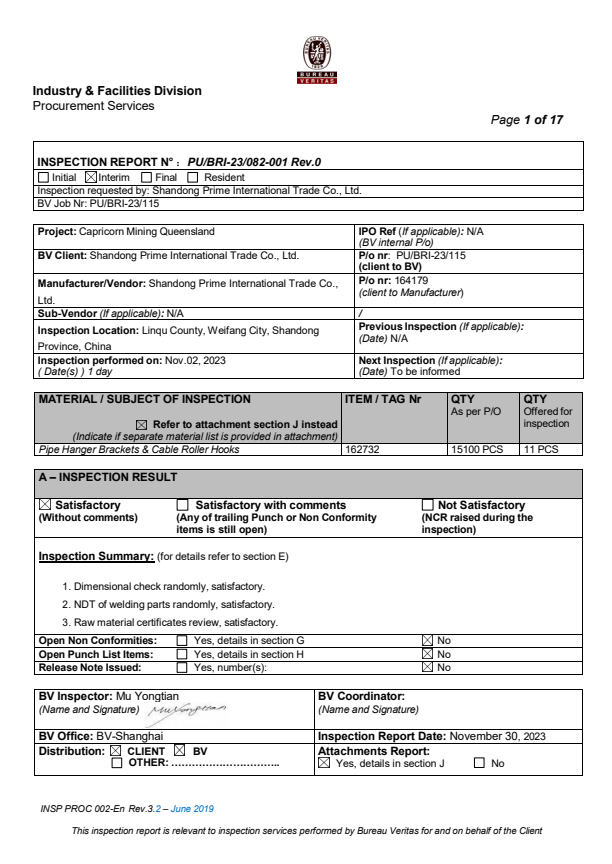

Quality Systems & Certifications

Our commitment to excellence is validated through rigorous international certifications, proprietary patents, and comprehensive quality management systems.

ISO 9001:2015 Certification

International standard for quality management systems, ensuring consistent quality and customer satisfaction across all production processes.

- Process Standardization

- Continuous Improvement

- Customer Focus

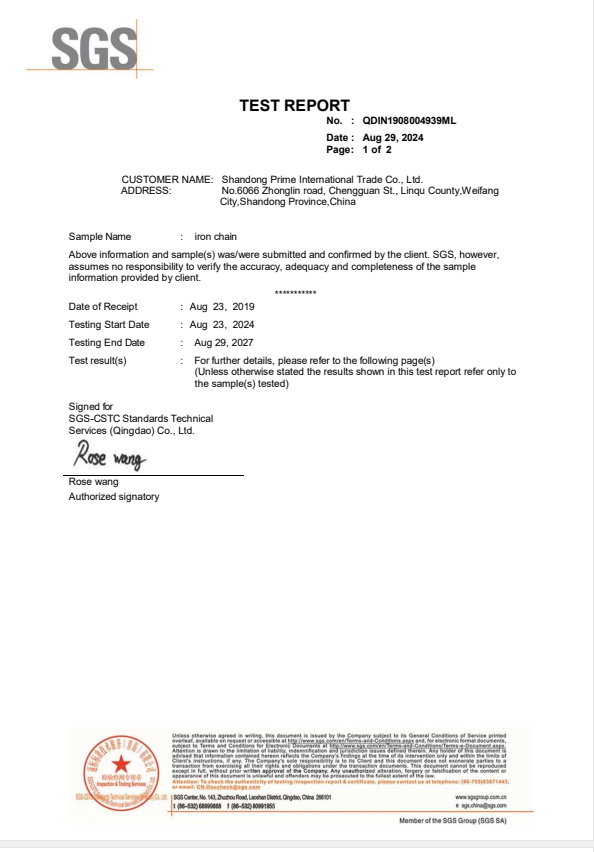

SGS Quality Verification

Global leader in inspection, verification, testing and certification services validating our quality standards and material integrity.

- Material Testing

- Quality Inspection

- Global Recognition

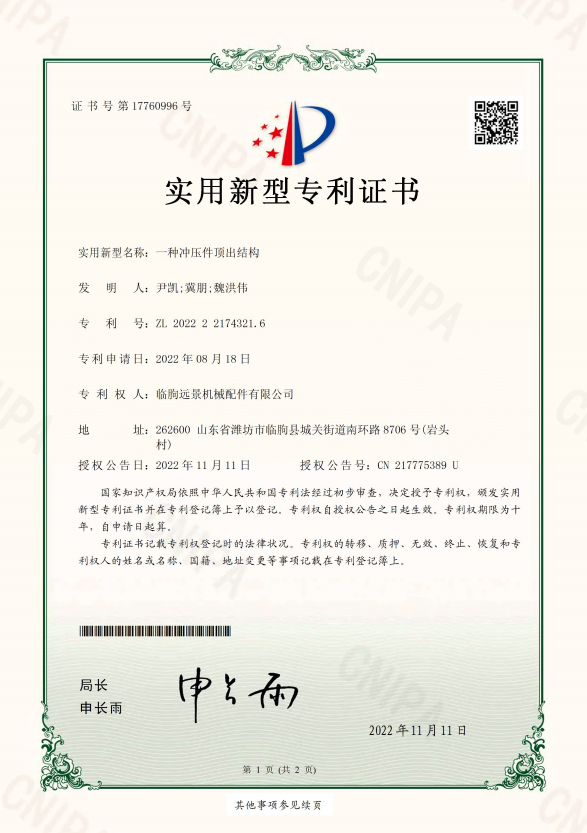

Proprietary Patents

Innovative casting technologies and processes protected by multiple patents, ensuring superior quality and production efficiency.

- Advanced Casting Methods

- Process Optimization

- Quality Enhancement

Get customization Quotation

With 30 years of professional experience and ISO-certified quality, we provide you with the highest quality metal casting solutions.

Your privacy, our commitment

Our company strictly adheres to international privacy protection standards to ensure the security and reliability of your business information.

Information encryption protection

SSL encryption technology is used to ensure secure data transmission.

Strict confidentiality agreement

We will never disclose your business information to any third party.

Professional team service

Professional response within 24 hours, one-on-one service

ISO certified quality

30 years of industry experience, a trustworthy partner

Contact information:

Phone:+86-185-5365-4726

Email address:[email protected]

Address: Dongcheng Industrial Park, Linqu County, Shandong Province